THE FULL LAMINATING PROCESS EXPLAINED:

1.REMOVE THE MODEL FROM THE PRINTER(SLOWLY

2.CUT THE NOSE AWAY FROM THE BASE WITH SOME SIDE CUTTERS

3.GENTLY BREAK AWAY THE FIN FROM THE SUPPORT MATERIAL

4.PLACE FIN IN A SPECIAL LAMINATING JIG FIGURE 4

(WEAR DISPOSEABLE RUBBER GLOVES)

HOLD THE TIP OF THE FIN WITH YOUR FINGER & RUBBER GLOVES:

5.USE 2 PART EVERCLEAR AVIATION RESIN 2:1 (2 PARTS RESIN & 1

PART HARDNER.

GIVE THE FIN A GENEROUS COATING FROM THE TOP OF THE FIN TO

JUST BEFORE THE MOUNTS (DO NOT SPILL TOO MUCH ONTO

THE MOUNTS.)

CLEAN THE BRUSH OVER THE MOUNTS MAKING SURE THE EXCESS

RESIN FILLS THE LITTLE CAVITIES BETWEEN THE FIN & THE TAB.

DO NOT TURN OVER UNTIL DRY AS THE RESIN IN THOSE CAVITIES

WILL COME OUT & MAKE A MESS.

LET THE FIN DRY WITH THE CORRIGATIONS FACING UP>

THE RESIN HAS TO POOL INTO THE CORRIGATIONS.

6.AFTER A FULL DAY THE RESIN WILL BE WORKABLE,YOU THEN PUT

THE FIN IN THE SPECIAL 3D PRINTED FIN SHAPING HOLDER FIGURE 1

AVAILABLE AT SHOPIFY AS A PRINT:

7.YOU ORGANISE A SET OF HAND SANDERS WITH VARYING GRADES

OF EMERY PAPER & A BUCKET OF WATER.(YOU CUT YOUR OWN PAPERS)

GRADES 180-360-1200 FIGURE 2

8.DIP 180 GRIT SHEET SANDER IN THE WATER & START SANDING THE FIN:

START WITH THE OUTER SHAPE FIRST,GET THE LEADING EDGE RIGHT

& THE TAIL WIDTH DOWN TO 3MM.

THEN WORK DOWN THE SIDES OF THE FIN UNTIL THE LAYER LINES DISAPPEAR

SO THAT YOU CAN HARDLY SEE THE LAYER LINES IN THE FIN:

USE THE SPECIAL 3D PRINTED D TOOL TO SHAPE THE BACK ANGLE FIGURE 3

DOWNLOADED FROM SHOPIFY.

THE IDEA IS THAT YOU FOLD UP A PIECE OF 180 GRIT & GAFF TAPE IT AROUND

THE D SHAPE PLASTIC TOOL:FIGURE 6

THEN USE A MULTITOOL TO HONE DOWN THE RIDGE AT THE BACK OF THE

FIN:YOU NEED TO BRING THE BACK ANGLE DOWN TO A SHARPER EDGE.

8A.YOU THEN NEED TO GET A HAND FILE & CLEAN UP THE MOUNTING

TABS SO THE THE FIN WILL FIT INTO THE SURFBOARD.

TO DO THIS YOU DOWNLOAD THE SPECIAL 3D PRINTED FIN

TESTER BOX FROM THE SHOPIFY STORE FIGURE 5

9.AFTER THAT , FOLLOW UP WITH 360 GRADE OF EMERY UNTIL

YOU GOT AN AWSOME FINISH.!!!!!!MATT FINISH:

10.THEN APPLY YOUR DECAL OR WATERPROOF STICKERS

11.SECOND COAT TO BE APPLIED.LIGHT COAT ONLY

FILL THE RESIN CAVITIES ON THE MOUNTS ON YHE OTHER SIDE.

12.REPEAT SANDING PROCESS OVER THE DECALS & VERY FINE

EMERY TO POLISH FIN UP TO A DULL BUT BEAUTIFULL MATT FINISH.

13.FINISH UP WITH 1200 EMERY & WATER TO GIVE A SEMI-GLOSS FINISH:

14.COLORING THE FINS.THIS IS DONE BY USING VERY SPECIAL ACRYLIC

PAINT FROM THE GRAFFITI INDUSTRY CALLED MONTANA-GOLD.

THIS IS A VERY SPECIAL PAINT THAT COMES IN A LOW PRESSURE CAN

& CAN DO A CLOSE UP ACCURATE SPRAY OF THE FIN ON THE JIG

IN YOUR HANDS,THAT QUICK DRIES TO AN INCREDIBLE DUST FREE

SMOOTH PROTECTIVE COATING OF MANY COLORS WITHIN 5 MINUTES !!!!!!

IT IS NOTHING LIKE NORMAL SPRAYPAINT.!!!!!

WARNING !!!WEAR A MASK-THERE ARE SOME CHEMICALS IN THIS CAN THAT

I CANNOT PRONOUNCE

1.REMOVE THE MODEL FROM THE PRINTER(SLOWLY

2.CUT THE NOSE AWAY FROM THE BASE WITH SOME SIDE CUTTERS

3.GENTLY BREAK AWAY THE FIN FROM THE SUPPORT MATERIAL

4.PLACE FIN IN A SPECIAL LAMINATING JIG FIGURE 4

(WEAR DISPOSEABLE RUBBER GLOVES)

HOLD THE TIP OF THE FIN WITH YOUR FINGER & RUBBER GLOVES:

5.USE 2 PART EVERCLEAR AVIATION RESIN 2:1 (2 PARTS RESIN & 1

PART HARDNER.

GIVE THE FIN A GENEROUS COATING FROM THE TOP OF THE FIN TO

JUST BEFORE THE MOUNTS (DO NOT SPILL TOO MUCH ONTO

THE MOUNTS.)

CLEAN THE BRUSH OVER THE MOUNTS MAKING SURE THE EXCESS

RESIN FILLS THE LITTLE CAVITIES BETWEEN THE FIN & THE TAB.

DO NOT TURN OVER UNTIL DRY AS THE RESIN IN THOSE CAVITIES

WILL COME OUT & MAKE A MESS.

LET THE FIN DRY WITH THE CORRIGATIONS FACING UP>

THE RESIN HAS TO POOL INTO THE CORRIGATIONS.

6.AFTER A FULL DAY THE RESIN WILL BE WORKABLE,YOU THEN PUT

THE FIN IN THE SPECIAL 3D PRINTED FIN SHAPING HOLDER FIGURE 1

AVAILABLE AT SHOPIFY AS A PRINT:

7.YOU ORGANISE A SET OF HAND SANDERS WITH VARYING GRADES

OF EMERY PAPER & A BUCKET OF WATER.(YOU CUT YOUR OWN PAPERS)

GRADES 180-360-1200 FIGURE 2

8.DIP 180 GRIT SHEET SANDER IN THE WATER & START SANDING THE FIN:

START WITH THE OUTER SHAPE FIRST,GET THE LEADING EDGE RIGHT

& THE TAIL WIDTH DOWN TO 3MM.

THEN WORK DOWN THE SIDES OF THE FIN UNTIL THE LAYER LINES DISAPPEAR

SO THAT YOU CAN HARDLY SEE THE LAYER LINES IN THE FIN:

USE THE SPECIAL 3D PRINTED D TOOL TO SHAPE THE BACK ANGLE FIGURE 3

DOWNLOADED FROM SHOPIFY.

THE IDEA IS THAT YOU FOLD UP A PIECE OF 180 GRIT & GAFF TAPE IT AROUND

THE D SHAPE PLASTIC TOOL:FIGURE 6

THEN USE A MULTITOOL TO HONE DOWN THE RIDGE AT THE BACK OF THE

FIN:YOU NEED TO BRING THE BACK ANGLE DOWN TO A SHARPER EDGE.

8A.YOU THEN NEED TO GET A HAND FILE & CLEAN UP THE MOUNTING

TABS SO THE THE FIN WILL FIT INTO THE SURFBOARD.

TO DO THIS YOU DOWNLOAD THE SPECIAL 3D PRINTED FIN

TESTER BOX FROM THE SHOPIFY STORE FIGURE 5

9.AFTER THAT , FOLLOW UP WITH 360 GRADE OF EMERY UNTIL

YOU GOT AN AWSOME FINISH.!!!!!!MATT FINISH:

10.THEN APPLY YOUR DECAL OR WATERPROOF STICKERS

11.SECOND COAT TO BE APPLIED.LIGHT COAT ONLY

FILL THE RESIN CAVITIES ON THE MOUNTS ON YHE OTHER SIDE.

12.REPEAT SANDING PROCESS OVER THE DECALS & VERY FINE

EMERY TO POLISH FIN UP TO A DULL BUT BEAUTIFULL MATT FINISH.

13.FINISH UP WITH 1200 EMERY & WATER TO GIVE A SEMI-GLOSS FINISH:

14.COLORING THE FINS.THIS IS DONE BY USING VERY SPECIAL ACRYLIC

PAINT FROM THE GRAFFITI INDUSTRY CALLED MONTANA-GOLD.

THIS IS A VERY SPECIAL PAINT THAT COMES IN A LOW PRESSURE CAN

& CAN DO A CLOSE UP ACCURATE SPRAY OF THE FIN ON THE JIG

IN YOUR HANDS,THAT QUICK DRIES TO AN INCREDIBLE DUST FREE

SMOOTH PROTECTIVE COATING OF MANY COLORS WITHIN 5 MINUTES !!!!!!

IT IS NOTHING LIKE NORMAL SPRAYPAINT.!!!!!

WARNING !!!WEAR A MASK-THERE ARE SOME CHEMICALS IN THIS CAN THAT

I CANNOT PRONOUNCE

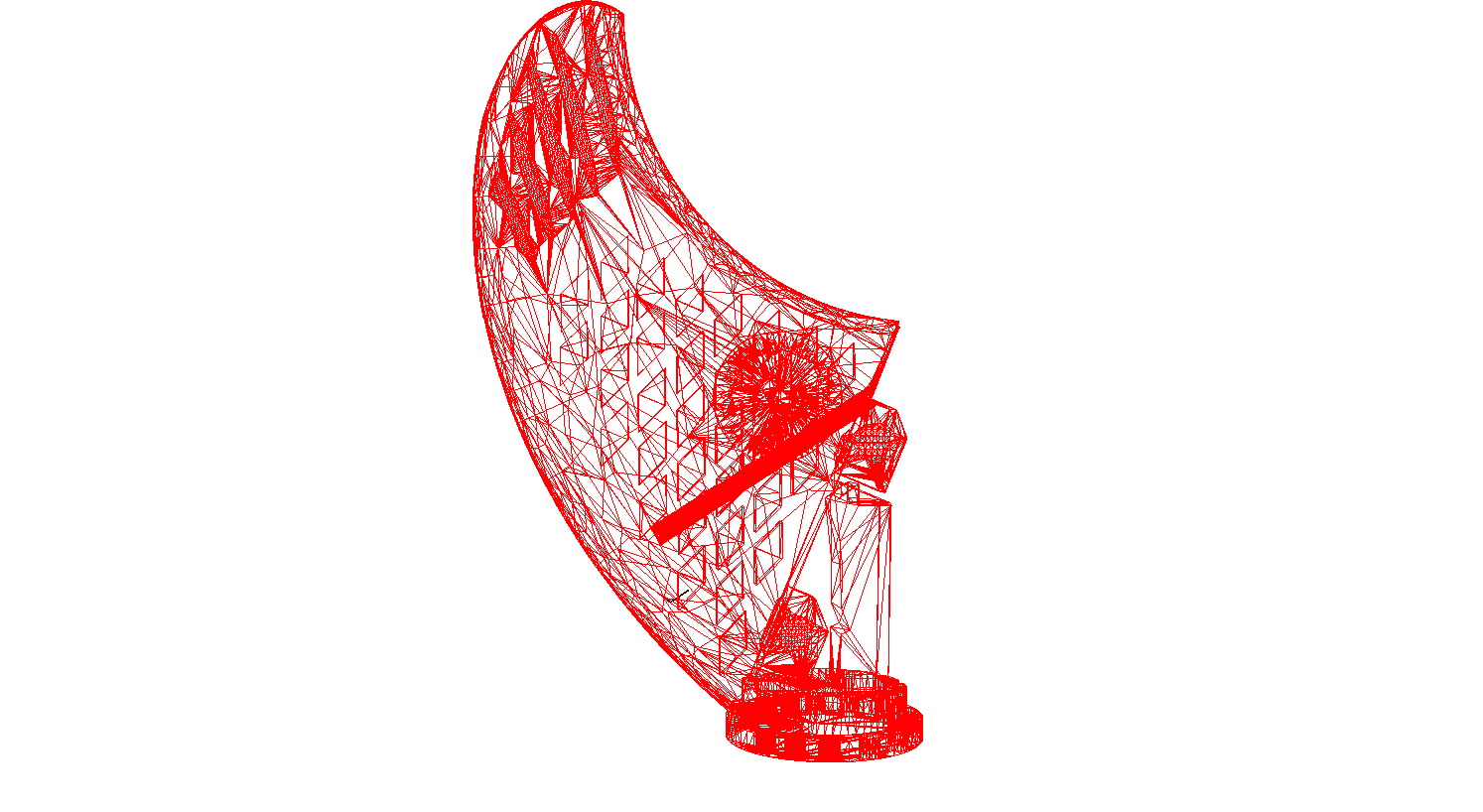

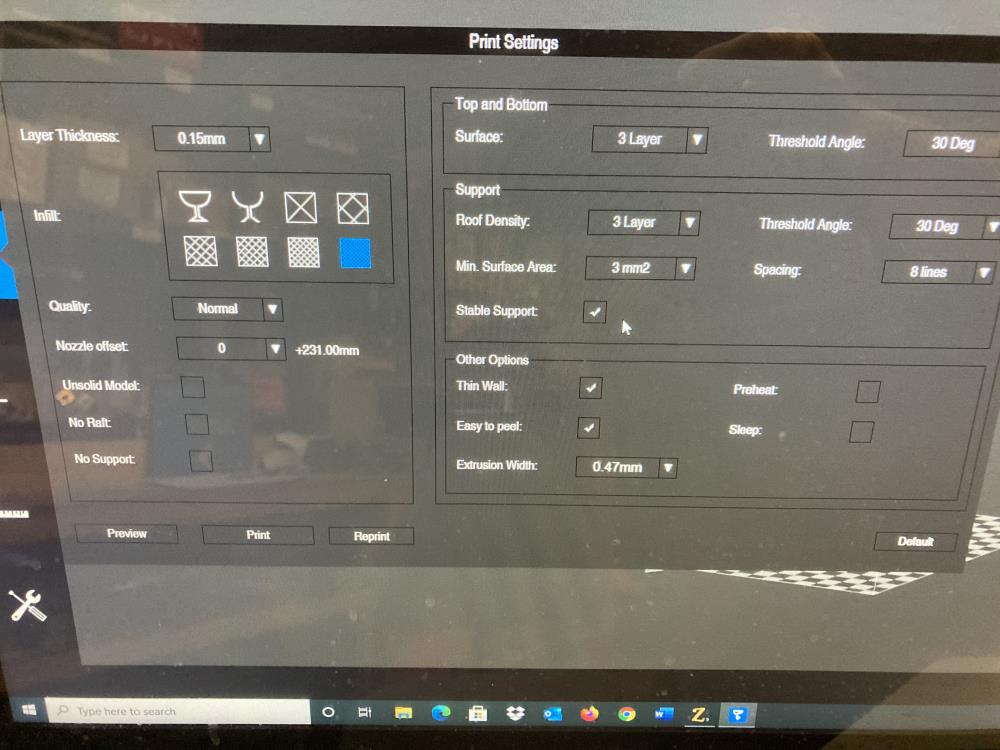

WARP SOAK BASE (ABSORBES BASE WARPAGE )

4.5MM HOLE FOR MOUNTING & BAMBOO RIB

INTERNAL DIAMOND GRILL TO

REDUCE WEIGHT & TAKE OUT

INTERNAL TENSION

REDUCE WEIGHT & TAKE OUT

INTERNAL TENSION

CORRIGATIONS IN TAIL

TO GIVE EXTRA STRENGTH

AFTER LAMINATION &

CREATE A SLIGHT WATER

TENSION BREAKER

TO GIVE EXTRA STRENGTH

AFTER LAMINATION &

CREATE A SLIGHT WATER

TENSION BREAKER

CADDED MOUNTS FOR EXTRA STRENGTH & STABILITY

(NOSE IS ATTACHED TO BASE,NEEDS TO BE CUT OFF WITH

SIDECUTTERS)

(NOSE IS ATTACHED TO BASE,NEEDS TO BE CUT OFF WITH

SIDECUTTERS)

LITE-HEAD WATERMARK FOR COPYRIGHT PROTECTON

118MM CENTRE FIN

STL FILE BLANK FOR

LAMINATION/SHAPE

STL FILE BLANK FOR

LAMINATION/SHAPE

(PLEASE DO NOT CREATE ONE USE PLASTICS

THE OCEAN HAS A CONTINENT OF PLASTIC

3 TIMES THE SIZE OF FRANCE!!!!!!:

USE POLYCARBONATE & LAMINATE IT

WITH RESIN )

THE OCEAN HAS A CONTINENT OF PLASTIC

3 TIMES THE SIZE OF FRANCE!!!!!!:

USE POLYCARBONATE & LAMINATE IT

WITH RESIN )

CLICH HERE ON LOGO

EVERCLEAR 2 PART RESIN

FIGURE 2 HAND SANDERS

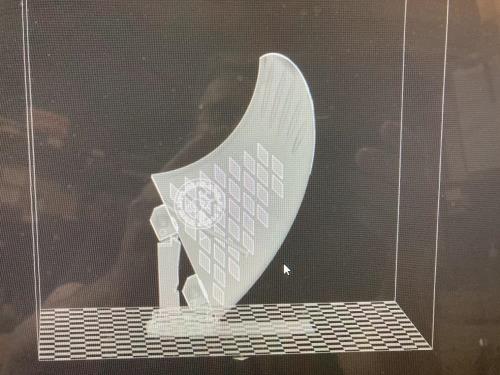

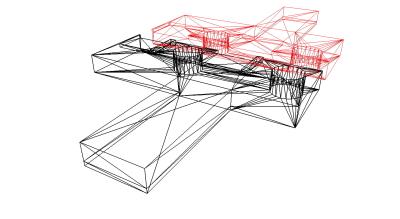

3D PRINT PARAMETERS FOR TIERTIME UP BOX

THIS IS THE PRINT IN THE SLICER SOFTWARE.

IT JUST SITS FLAT ON THE PLATFORM IN THE CENTRE.

THE SAME PARAMETERS WOULD APPLY TO ANY DESKTOP

PRINTER .THE NOZZLE SHOULD BE SET FOR POLYCARBONATE.

250-280 DEGREES.

GET THE BENCH UP TO MAX TEMP 90 DEGREES PLUS TO

GET A STRONG PRINT WITH A MINIMUM WARP.

IT JUST SITS FLAT ON THE PLATFORM IN THE CENTRE.

THE SAME PARAMETERS WOULD APPLY TO ANY DESKTOP

PRINTER .THE NOZZLE SHOULD BE SET FOR POLYCARBONATE.

250-280 DEGREES.

GET THE BENCH UP TO MAX TEMP 90 DEGREES PLUS TO

GET A STRONG PRINT WITH A MINIMUM WARP.

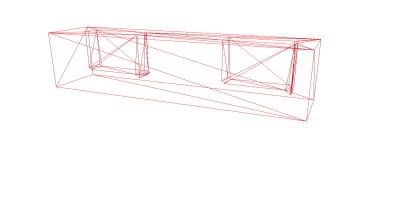

FIGURE 4 THE LAMINATING JIG

FIGURE 1 SHAPING HOLDER

FIGURE 3 D BACKSHAPE TOOL

FIGURE 5 TESTER BOX

FIGURE 1 SHAPING HOLDER

FIGURE 3 D SHAPE BACK ANGLE TOOL

FIGURE 5 TESTER BOX

BEST PRINT FILAMENTS FOR LITE-HEAD FINS